News

- 2024.05.09Release

- Expanding the Use of Recycled Plastic to Products Outside the Company: NEC Platforms' Wi-Fi Router "Aterm" Exterior Components<NEW!>

- 2024.05.09News

- "Matelier, Plastics that Contribute to the Environment" website is now open.<NEW!>

Matelier came about in an era when environmental concerns are an issue

The Sustainable Development Goals (SDGs) were adopted in 2015 as common goals for the international community to create a sustainable world. The SDGs are 17 goals that comprehensively encompass issues facing society, and one of the goals stipulates “climate action.” In order to cope with climate change in forms such as extreme heat and heavy rainfall, governments and businesses in various countries must take action in various forms.

In addition, consumption of the resources that humans need is estimated to reach the equivalent of two Earths by 2030 as the world’s population grows. In order to make effective use of limited resources, resource consumption needs to be reduced and collection networks and material technologies that help with resource recycling need to be created.

Our Matelier, a line of recycled plastics, came about in an era when environmental considerations are an issue.

The name “Matelier” is a portmanteau combining the words “material” and “sommelier.” A sommelier is a wine specialist. Like a sommelier, we will be a sommelier of recycled plastic (an environmentally friendly material) and provide services that take the circumstances and needs of our customers into account.

What is Matelier?

To address global environmental issues, we formulated “Eco Vision 2050" in 2009, our long-term environmental vision for the year 2050. We have set such goals as “reducing CO2 emissions throughout the product lifecycle to net zero by 2050” and “reducing the use of the Earth’s natural resources in our products by 90% or more compared to 2019 by 2050”.

To achieve the goals set in Eco Vision 2050, we are working on various measures, one of which is promoting the recycling of plastic.

Since 2011, we have been using recycled plastic (an R-PET-based alloy) made from waste plastic in the interior components of our multifunction printers (MFPs), which require greater functionality. In conjunction with the production of this recycled plastic, we have developed high purification technology and upgraded recycling technology that maximize the reduction of our environmental impact. By using these technologies to produce recycled plastic, we have succeeded in both “reducing our environmental impact” and “achieving the functionality required for MFPs.”

Matelier was created using the high purification technology and upgraded recycling technology that we have developed over the years.

Matelier is a line of recycled plastics with a high percentage of constituents derived from waste plastic and dramatically improved strength and flame retardance compared to waste plastic. Moreover, these recycled plastics effectively reduce CO2 more than virgin plastic.

| Matelier’s effect at reducing CO2 compared to virgin plastic (*1) | |

|---|---|

| The Matelier Product Lineup | Maximum effects of CO2 reduction |

| R-ABS (standard) |

▲81% |

| R-ABS (flame-retardant) |

▲77% |

| R-PC (high strength) |

▲90% |

| R-PC/PET (high ratio of recycled plastic) |

▲69%(※2) |

*1In-house calculation of the efficiency of reduction to the point where recycled plastic (pellets) is produced at the plant.

*2Compared to V-PC/ABS

What Konica Minolta can do

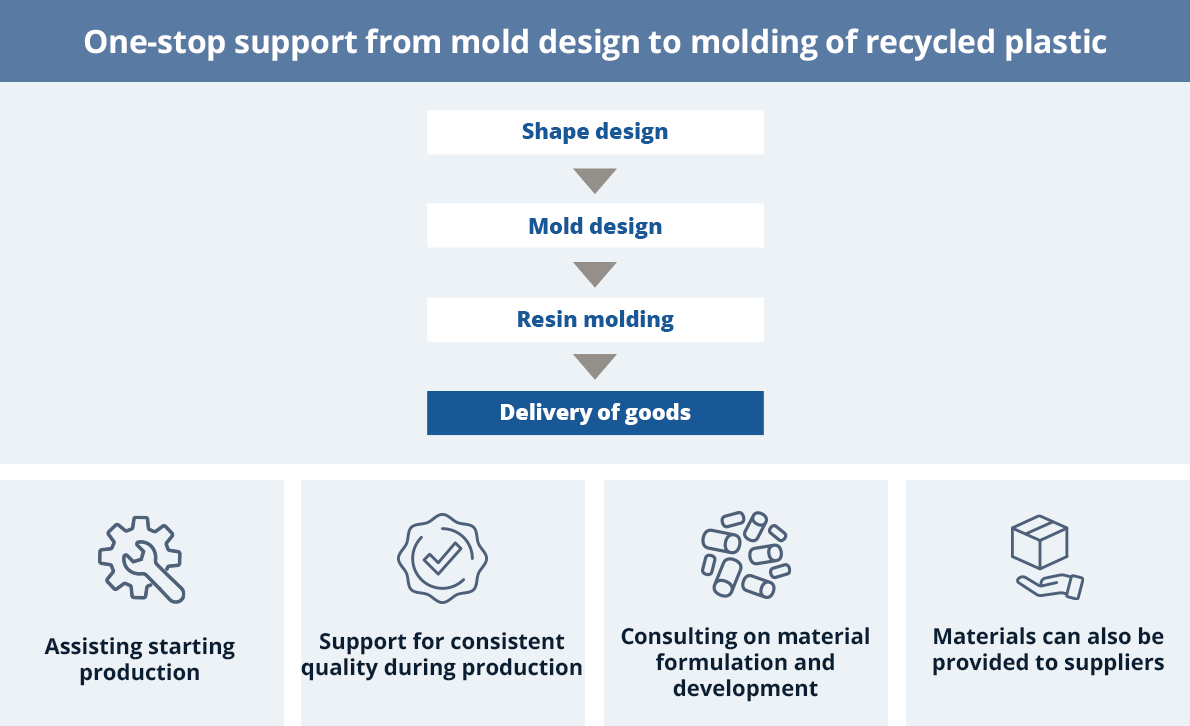

We support the development and supply of recycled plastic as well as molding

Matelier is a line of recycled plastics (environmentally friendly materials) as well as manufacturing technologies and a consulting service that we offer in accordance with our customers’ circumstances and needs.

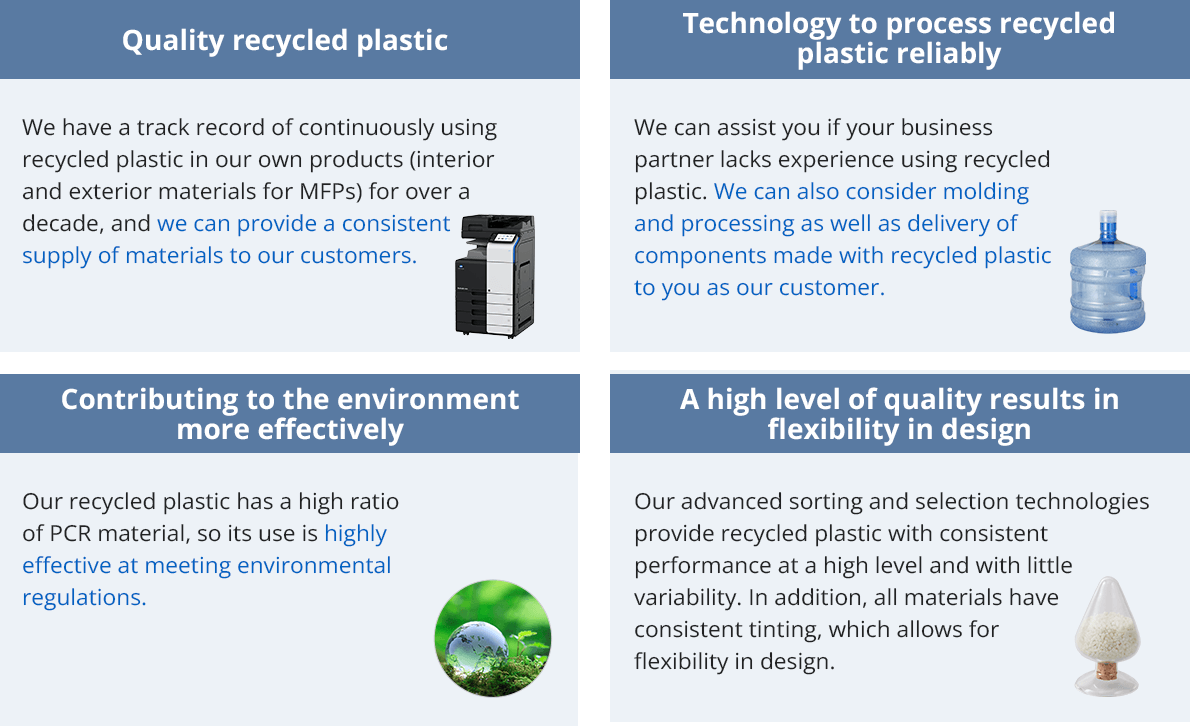

We have been using recycled plastics developed in-house for our MFPs for over a decade since 2011. There has been no shortage of raw materials during this period. Recently, other companies have also used our recycled plastic.

We develop and supply recycled plastic and we also mold components. As we have used recycled plastic in our products, we have amassed high purification technology, upgraded recycling technology, and molding technology. With these technologies, we can provide recycled plastic and we can also supply it in the form of molded components and support customers when molding recycled plastic at their plants.

In addition, our environmental goal is to be carbon negative by reducing our own CO2 emissions and those of our customers. This approach is possible because we are involved in every step, from the development of recycled plastic to molding.

*Ratio of PCR material: Percentage of waste-derived plastic contained in recycled plastic. If the ratio of PCR material is 100%, this means that the recycled plastic is made solely from waste-derived plastic.

Inquiries about our recycled plastic

Products

Matelier utilizes waste materials that have a short usage period and relatively little deterioration. For example, milk bottles, water bottles, PET bottles, and other bottles that are discarded as soon as they are finished drinking are used as raw materials. In addition, CDs and DVDs used indoors or in cars, and amusement machines that are used in air-conditioned rooms and whose models are changed every 3 to 5 years are also utilized.

Technology

The recycled plastic developed by Konica Minolta is used in the housing of MFPs, which require highly functional materials, through high-purity and upgrade recycling technologies. These technologies have the potential to expand the use of waste plastics and contribute to the realization of a sustainable, recycling-oriented society by reducing environmental impact.

Message

Recycled plastics must offer the same or better quality, cost, and supply as petroleum-derived virgin plastics, as well as high environmental performance, making the formulation design extremely challenging. We achieved our goal by designing the entire process, including the production process, while making full use of material design/analysis/evaluation technology, one of our core technologies.

Case

Konica Minolta has been accumulating recycled plastic technology for more than 10 years. Konica Minolta has been using recycled plastic obtained through material recycling in its MFPs for more than 10 years.

FAQ

Konica Minolta utilizes raw materials for PCR materials that have a fast replacement cycle and relatively little degradation, so there is little variation in physical properties, ensuring that the properties are almost the same as those of virgin materials.