System

Environmental Management System

Promotion system

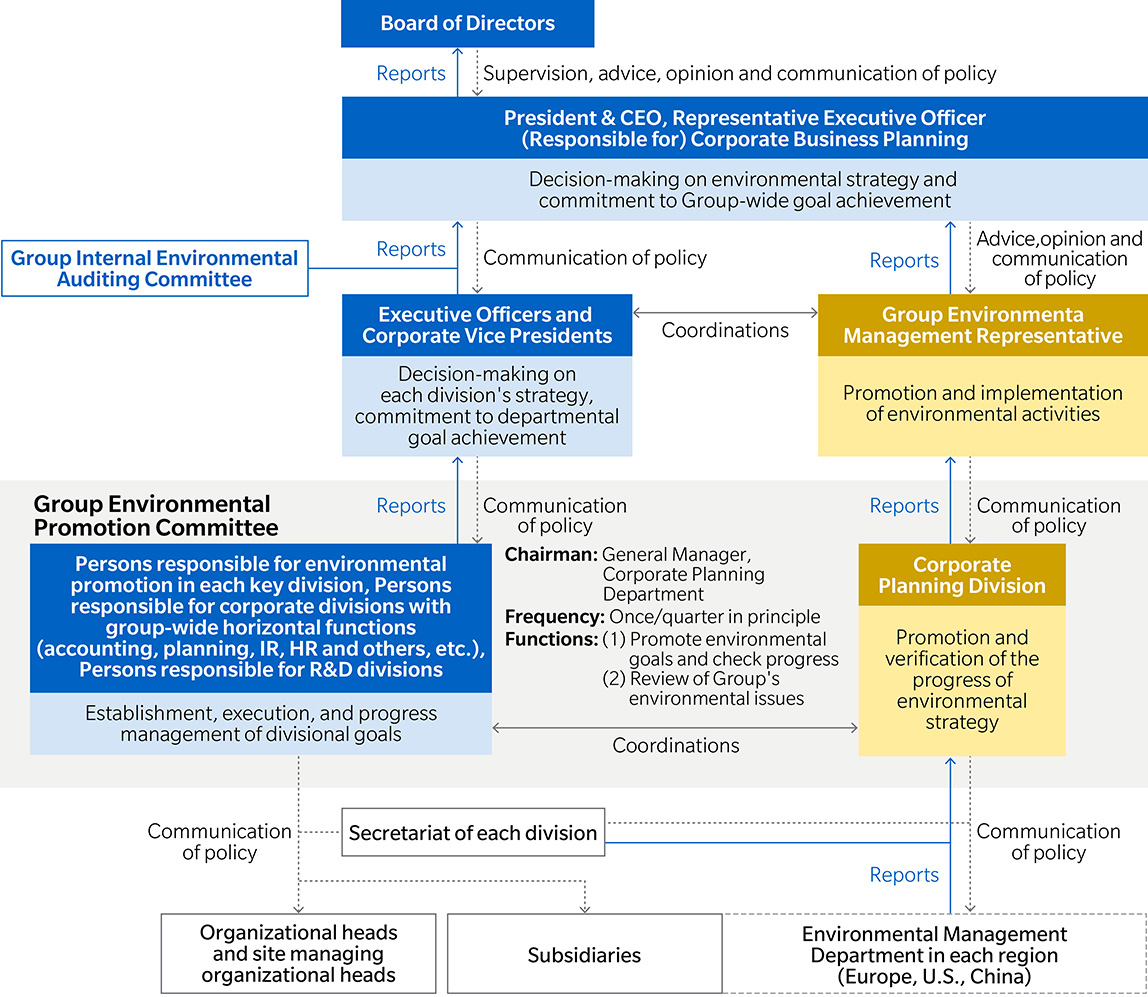

All aspects of environmental management are overseen by the President and CEO of Konica Minolta, Inc.

The President has ultimate responsibility for and authority over all environmental management including climate change issues and is also accountable for its effectiveness. The President appoints the Group Environmental Officer to lead and promote environmental management and handle environmental measures. The Group Environmental Officer formulates a medium-term environmental plan, which is then approved by the Board of Directors as a corporate management plan. In addition, the Group Environmental Officer reports monthly to the President and the Audit Committee, established by the Board of Directors, on the progress made in environmental management. The Audit Committee continuously monitors and verifies the overall execution status of environmental management, primarily led by the President and CEO.

Discussions and decisions regarding important environmental issues occur at management councils and other meetings attended by the President and CEO, executive officers, and corporate vice presidents. This aims to improve the linkage with management and business strategies, treating environmental issues similarly to other critical management challenges.

Konica Minolta has also established the Environmental Promotion Committee as an organization to deliberate and promote medium-term environmental plans for the entire group. The Head of Corporate Planning Division this committee. Environmental promotion managers, appointed as heads of business and corporate divisions, participate in deliberating medium-term and annual environmental plans, quarterly progress, and environmental issues facing the Group.

Environmental Audits

At Konica Minolta, the Internal Environmental Auditing Committee directs the internal environmental auditing for the entire Group.

Through internal environmental audits, which are conducted at least once a year, the Group verifies the adequateness and effectiveness of management systems. Additionally, by checking the implementation status of the medium-term plan, audits ensure that management systems are functioning effectively in all the Group's organizations.

Environmental Management System

Operating management system based on ISO 14001

To raise the efficiency of environmental management throughout the Group, Konica Minolta operates its management system based on ISO 14001 and has established a basic policy requiring all group production sites worldwide to obtain ISO 14001 certification.

Konica Minolta is engaged in Green Products, Green Factory, and Green Marketing activities throughout the product lifecycle. In addition, targets are set within these activities to help solve business and environmental issues, integrating environmental efforts into core business activities. This approach is consistent with ISO 14001:2015.

Environmental Risk Management

Konica Minolta treats environmental risks as business risks. Risks are managed under the Risk Management Committee, which is chaired by the officer in charge of risk management, who is appointed by the board of directors, to prevent risks from coming to a head.

The committee conducts risk assessments of corporate activities, and verifies the identified risks and necessary measures to minimize them. It also confirms and reviews whether the risk management system is functioning effectively. The findings of the Risk Management Committee are reported regularly to the Audit Committee, which consists of directors who are not also serving as executive officers. Risks that are particularly important in terms of management and business are reported to and discussed with the Board of Directors.

Konica Minolta views risks as “uncertainties that could affect the organization’s revenue and losses.” With the understanding that risks are not only negative, but are also opportunities with positive aspects, the company views risk management as an activity to curb the negative aspects of risk while maximizing returns.

Compliance with Environmental Regulations

As global environmental problems, including climate change and resource and energy issues, become more widespread and severe, extending to encompass entire regions, and indeed, the entire planet, government policies and regulations at the regional and national levels around the world are being reconsidered and strengthened in order to ensure sustainable growth.

As a global business enterprise, Konica Minolta is building its global compliance system to ensure that all of its production sites and sales offices comply with all legal regulations.

Konica Minolta is building management systems centered on environmental organizations in Europe, North America, China and Japan to ensure that production sites and sales companies in each region respond appropriately to environmental laws. Under these systems, steps are taken to comply with relevant laws and regulations, such as chemical substance regulations, restrictions on chemicals contained in products, recovery and recycling regulations and energy saving regulations.

In fiscal 2024, Konica Minolta continued to conduct status checks of all Group companies and found no serious violations of environment-related laws and regulations.

Product Assessment System

Konica Minolta ensures compliance with laws and regulations and strives to minimize its environmental impact by conducting equipment assessments when it installs, moves, or disposes of equipment, and product assessments when it develops or changes products.

Product assessment

When developing a new product, the Konica Minolta Group identifies the impact the product would have on the environment throughout its lifecycle, from its manufacture and distribution to its use and disposal, while setting evaluation criteria and carrying out assessments.

The Group sets targets in line with its own evaluation criteria for environmental impact, and carries out product assessments as part of its product commercialization flow. Only products whose status is checked and that have cleared the targets are sent to market. This rigorous process has ensured that Konica Minolta complies with the most recent environmental laws, properly manages hazardous chemical substances, improves the environmental performance of its products, and complies with various countries’ environmental labeling schemes.

Emergency Response

Reporting rules in the event of crises have been established to ensure that the company responds promptly and appropriately to crises caused by various risks. These rules have been thoroughly communicated to executive officers and its Group companies. In line with these reporting rules, the executive responsible for risk management takes the leading role in managing information on disasters and accidents that occur around the world and other crises.

Regarding the environment, emergency response procedures have been established at Group companies in Japan that have acquired integrated ISO 14001 certification. Based on the group-wide rules stipulated in the Konica Minolta Environmental Management Manual, each department has identified potential situations during an emergency or natural disaster that could have a significant impact on the environment. The departments have also established the necessary crisis response procedures, and they regularly training them. The training results are then reviewed and modified as necessary.

In accordance with emergency response guidelines created by each department, training is held at least once a year to help minimize damage in the event of a major accident. For example, evacuation drills are carried out to practice for a potential explosion caused by solvent ignition, and similar drills are done to prepare for a potential external chemical spill caused by chemical leakage into a rainwater drainage structure.

Each department has also established an emergency communication system to report to the officer responsible for environment on the same day as the incident, and all are working to take appropriate measures.

Environmental Education

Each Group company with integrated ISO 14001 certification provides a range of environmental education to its employees in order to enhance their awareness of and ability to perform environmental activities. Many employees participate in training programs to raise the level of the Group's environmental activities. The content ranges from specialized knowledge to the understanding of issues related to global environmental problems. At least once a year, training is given to new hires, internal environmental auditors, and those involved in chemical substance management related to products.